Elektron pochta formatida xato

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Yangiliklar

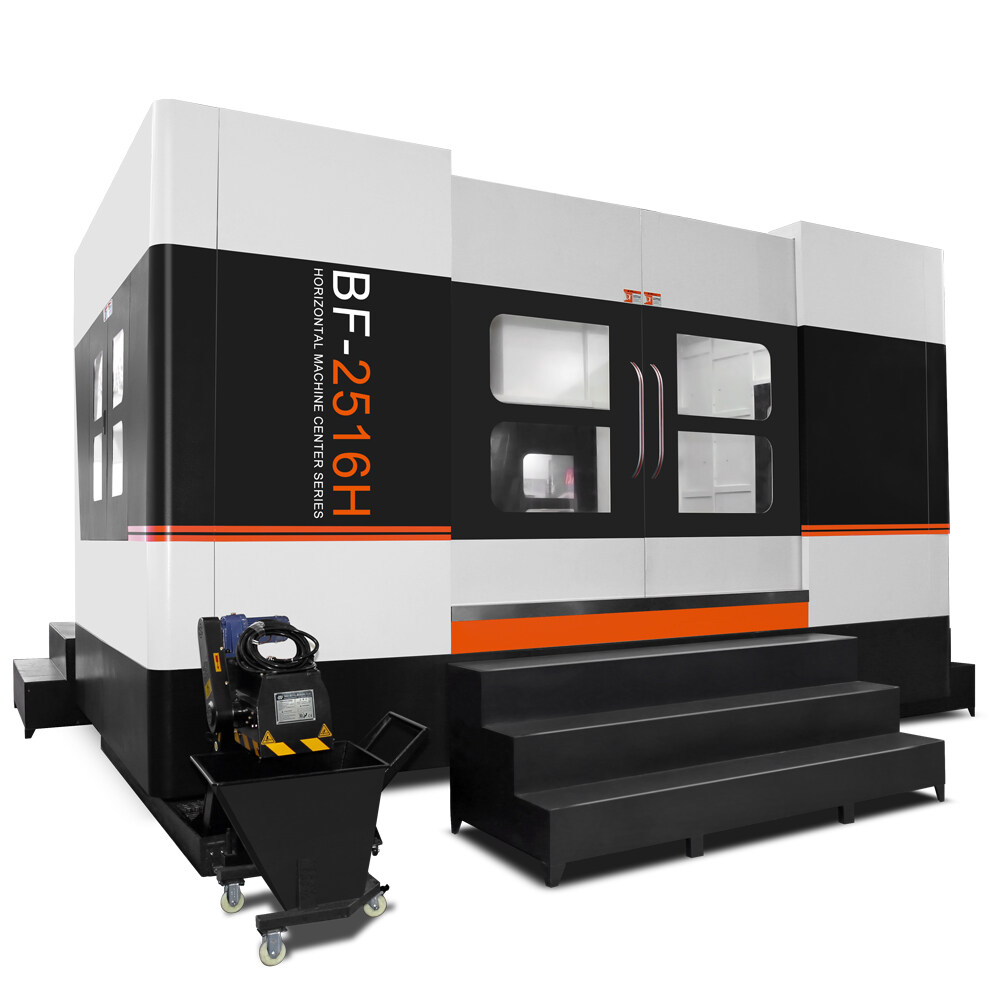

Four Key Points for Using CNC Horizontal Machining Center

The horizontal CNC machining center refers to the machining center where the workbench is set parallel to the spindle. It usually has three linear motion coordinate axes plus a workbench rotation axis. After clamping the workpiece at one time, the horizontal machining center can independently select different tools according to the program, automatically change the speed of the spindle, and complete the processing of multiple processes on multiple surfaces in sequence according to the programming sequence. This kind of machining center is suitable for processing box parts. Next, I will introduce the four key points for using horizontal machining centers.

Environment for installing horizontal machining center

The horizontal machining center should be installed far away from the source, not exposed to direct sunlight, with no heat radiation and no humidity. If there is a source near the place where the horizontal machining center is installed, an anti-vibration ditch should be set around the horizontal machining center. If the anti-vibration groove is not set, it will directly affect the machining accuracy and stability of the horizontal machining center. Over time, it will affect the poor contact of electronic components, failure, and the reliability of the horizontal machining center.

Voltage and current shall be strictly controlled

Horizontal machining centers are generally installed in the processing workshop, and there are many of mechanical equipment in the processing workshop, which inevitably leads to large fluctuations in the power grid. Therefore, the installation position of the horizontal machining center must strictly control the voltage and current of the power supply. The voltage and current of the power supply must be controlled within the allowable range of the horizontal machining center. The voltage and current of the power supply must be kept stable, otherwise, the normal work of the horizontal machining center will be directly affected.

Temperature and humidity will directly affect the horizontal machining center

Generally, the horizontal machining center can work normally only under an environment of less than 30 ℃. Generally, the distribution box of the horizontal machining center is equipped with exhaust fans and cooling fans to ensure that the electronic parts and central processing work at a constant temperature. If the temperature and humidity are too high, the service life of the components of the control system will be reduced, resulting in an unreasonable increase in the failures of the horizontal machining center. If the humidity increases, the dust will increase on the integrated circuit board, which will directly lead to the failure of poor contact and short circuit.

Factory parameter setting of machine tool

When using the horizontal machining center, customers cannot change the factory parameter settings of the machine tool at will, because these factory parameter settings are directly related to the dynamic characteristics of each component of the horizontal machining center, and only the gap compensation parameter values can be set according to the actual situation. If you want to change the factory setting parameters, you should contact the manufacturer and operate under the guidance of the manufacturer's technician to change the factory-set parameters.

We are a 5 axis horizontal machining center, new horizontal machining centers, horizontal turning centers wholesaler, our products satisfy our customers. And we want to be your long-term partner, any interests, welcome to contact us.