Elektron pochta formatida xato

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Yangiliklar

The Foundry Industry Is Moving from Traditional Casting to Intelligent Casting

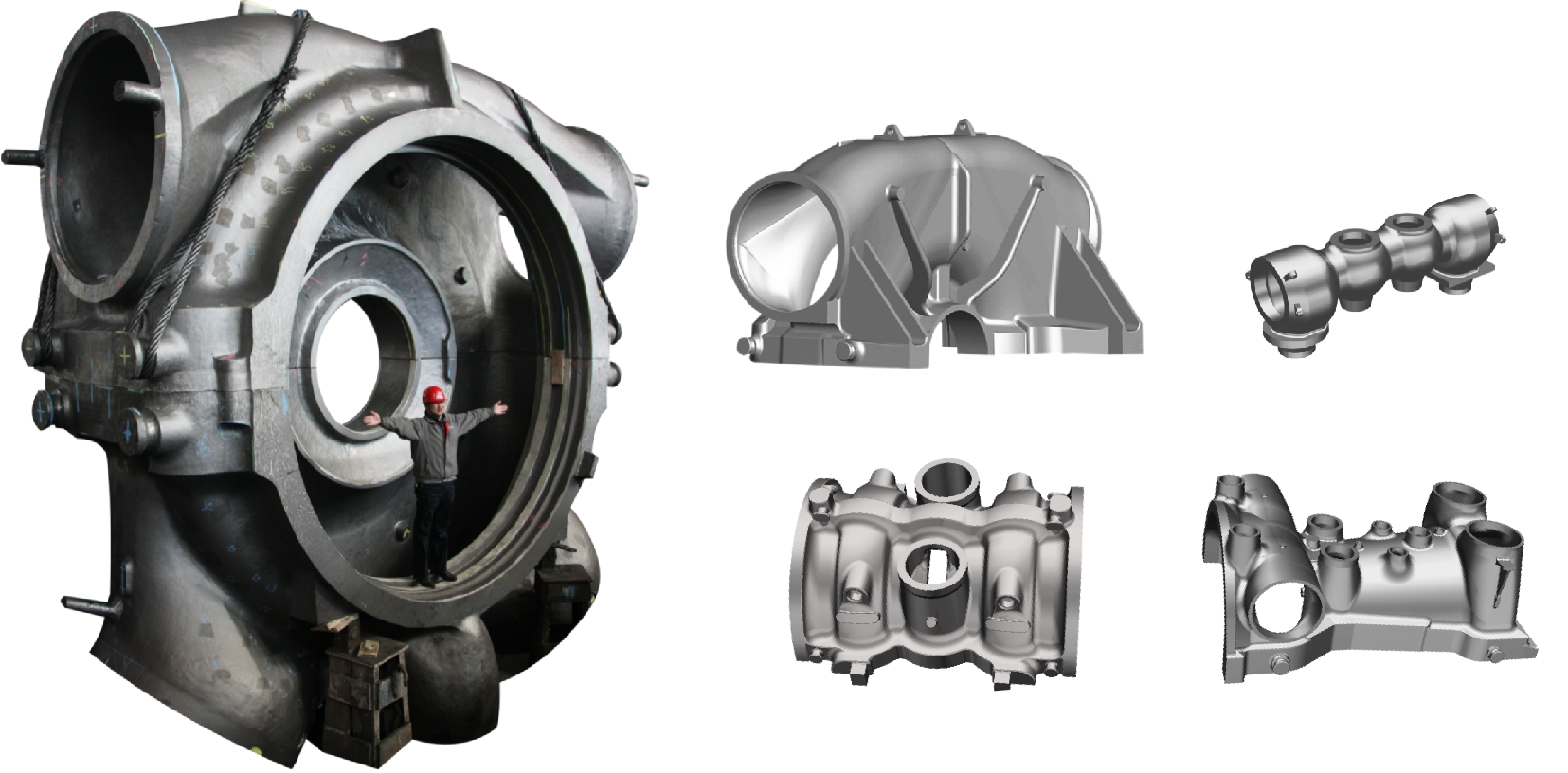

Casting is an ancient industry. Using the physical properties of materials, it can be formed into castings with complex shapes, different structures and different scales, and then processed into various products we need. There are many factors affecting the quality of castings, especially the occurrence of various casting defects. With the application of computer numerical simulation technology, it is to pre-examine product design at the technical level, refine and quantify process parameters, and use casting process simulation to free technicians from random phenomena such as trial and error in the casting process and design based on fuzzy feeling. It ensures that the design and manufacturing parameters of casting can be visualized and quantified, and promote the application of digitalization; every operation process of casting, especially key processes and key links, such as mold manufacturing, core manufacturing, coating baking, etc., are executed by Quantitative parameter control with a unified standard.

The successful application of today's 3D printing technology, industrial robots and other advanced technologies is to complete the unified and precise operation of the same product through the interaction of a large amount of data, ensuring the reproducibility of product manufacturing; online digital control is to get rid of the extensive management of traditional casting, to solve the problem of unstable quality of operators due to changes in emotional factors, environmental weather differences or personnel loss, etc., to ensure the consistency of mass product quality.

The traditional foundry industry faces serious problems

At present, there are still the following problems in China's traditional foundry industry, which need to be improved urgently.

One is that people in the Chinese foundry industry have poor awareness of environmental protection and consume a lot of energy. Foreign foundry companies are also paying attention to the importance of environmental protection while improving foundry technology, while Chinese foundry companies are relatively lacking in this regard, and have always been high Extensive development with high pollution and high consumption has not taken environmental protection measures.

The second is that China's foundry technology and equipment are relatively backward. China's technological level and equipment are relatively prominent only to a few key enterprises, and the product quality is far from meeting the requirements of new technology and new technology, while developed countries are technologically and equipment. High-end and automation are generally achieved.

The third is that the castings in China's foundry industry have low grades and poor precision. In terms of craftsmanship, they cannot be compared with foreign countries. Fourth, the scale of development is small and the economic benefits are poor. Although the growth rate of manufacturers in the foundry industry is accelerating every year, most of them are small workshop-style manufacturers with small scale and small investment in technology and manpower, so it is difficult to obtain considerable economic benefits. benefit.

It has become inevitable for the foundry industry to move from traditional to intelligent

In the new era of overwhelming big data, traditional foundry enterprises and traditional production methods are seriously challenged. The new words "smart casting" and "digitalization" bring hope and confusion. What exactly is "smart casting"? How far is it from us?

"Intelligent casting" is a product of high integration of informatization and casting production, including intelligent casting technology and intelligent casting system. Intelligent casting technology includes digital simulation, 3D printing, robots, ERP, etc. The intelligent casting system is a big data knowledge base with learning ability, which can carry out self-planning and self-improvement through the comparative analysis of environmental information and self-information.

The typical application mode of "Intelligent Foundry" is "Digital Foundry". The "Digital Foundry" adopts information technology to manage all internal processes such as production process, quality control process, financial process, product development process, human resource management training process, etc. Use information technology to deal with the related processes with suppliers and customers. The entire production process can be simulated and controlled. In the "digital foundry", heavy physical labor is basically eliminated, 80% of employees can work in air-conditioned rooms, the environment is clean, and production efficiency and benefits are greatly improved.

Conclusion

For more information about lost wax casting artist,metal lost wax casting,lost wax casting sterling silver, we are glad to answer for you.