Elektron pochta formatida xato

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Yangiliklar

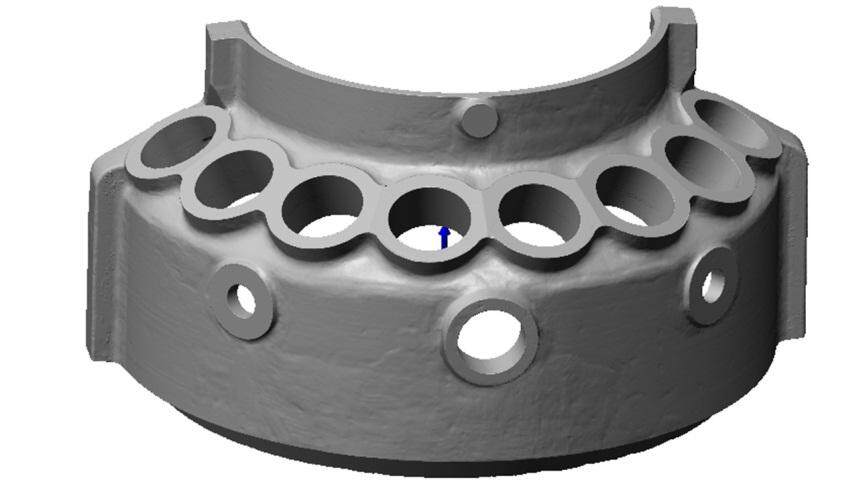

What is the Process of Nodular Cast Iron?

Due to the high content of carbon and silicon, nodular cast iron has the same good fluidity and self-feeding ability as gray cast iron. However, due to the difference in furnace pretreatment and solidification process, there are great differences in casting properties between nodular cast iron and gray cast iron, so their casting processes are also different.

Fluidity and pouring process of nodular cast iron

The addition of a nodulizing agent in the process of nodulizing treatment, on the one hand, reduces the temperature of molten iron, on the other hand, magnesium, rare earth, and other elements from slag inclusions in the ladle and gating system. Therefore, the fluidity of molten iron decreases after spheroidizing. At the same time, if these slag inclusions enter the mold cavity, they will cause casting defects such as inclusions, pinholes, rough casting surface, and so on.

To solve the above problems, the following problems should be paid attention to in the casting process of nodular cast iron:

- The scum on the molten iron surface of the ladle must be removed, It is better to use a teapot nozzle to pour the ladle.

- Strictly control the residual amount of magnesium, preferably below 0.06%.

- The gating system shall be of sufficient size to ensure that the molten iron can fill the mold cavity as soon as possible without turbulence.

- The semi-closed gating system is adopted. According to the data recommended by the American Foundry Society, the ratio of sprue, runner, and the gate is 4:8:3.

- The inner gate shall be opened at the bottom of the mold as far as possible.

- If the filter screen is placed in the gating system, it will help to eliminate the slag inclusion.

- Increasing the pouring temperature properly can improve the mold filling ability of molten iron and avoid carbide. For the molten iron treated with rare earth, the pouring temperature can be referred to the relevant manuals in China. For molten iron treated with magnesium, according to the data recommended by the American Foundry Society, when the wall thickness of the casting is 25mm, the pouring temperature shall not be lower than 1315 ℃; When the wall thickness of the casting is 6mm, the pouring temperature shall not be lower than 1425 ℃.

Solidification characteristics and feeding process characteristics of nodular cast iron

Compared with gray cast iron, nodular cast iron has very different solidification characteristics, mainly in the following aspects:

- The eutectic solidification range of nodular cast iron is wide. During the eutectic solidification of gray cast iron, the end of flake graphite is always in contact with molten iron, so the eutectic solidification process proceeds faster. Because the graphite ball of nodular cast iron is surrounded by an austenite shell at the later stage of growth, its growth needs to be carried out through the diffusion of carbon atoms, so the solidification process is slow so that it is required to maintain the eutectic solidification by forming new graphite crystal nuclei on the new graphite heterogeneous core under greater undercooling. Therefore, there is a wide liquid-solid coexistence area on the section of ductile iron during solidification, and its solidification model has the characteristics of porridge solidification. This makes it difficult to feed nodular cast iron during solidification.

- Ductile iron has many graphite cores. After spheroidization and inoculation, the graphite core of nodular cast iron is much more than that of gray cast iron, so the size of the eutectic is much smaller than that of gray cast iron.

- Nodular cast iron has a large eutectic expansion force. Because graphite is quickly surrounded by austenite shell during eutectic solidification of nodular cast iron, the expansion caused by volume increase during graphite growth cannot be transferred to molten iron, resulting in a large eutectic expansion force. When the mold stiffness is not high, the resulting eutectic expansion will cause shrinkage defects.

- The volume change of nodular cast iron during solidification can be divided into three stages: the liquid Shrinkage from molten iron pouring into the mold to cooling to eutectic temperature, the volume expansion caused by the precipitation of graphite balls during eutectic solidification, and the volume shrinkage during cooling after molten iron solidification.

Due to the above solidification characteristics, from the perspective of feeding, ductile iron has the following characteristics in the casting process:

- The mold should have high compactness to make the mold have enough rigidity to resist the eutectic expansion force of nodular cast iron during eutectic solidification. It should be noted that at this time, proper measures should be taken to improve the air permeability of the mold, and the moisture in the molding sand should be reduced as much as possible to prevent "fire choking".

- Reasonably set the pouring and riser. The riser of nodular cast iron is different from ordinary steel and white iron. The rationality of setting the riser of nodular cast iron is that it can fully supplement the liquid shrinkage of molten iron. When the molten iron enters the eutectic expansion stage, the pouring system and riser neck are frozen in time, so that the castings can use the expansion precipitated from graphite for self-feeding.

- The sandbox shall have sufficient rigidity, and there shall be a firm fastening device between the upper box and the lower box.